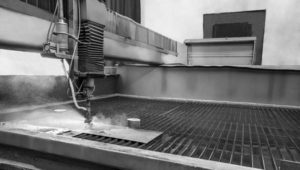

High quality water jet ball screw repair services performed on-site, so you are back to cutting quality parts quickly.

Water jet ball screw repair services that restore cut accuracy. Maintaining your water jet ball screws does not have to be expensive. It just has to be done right!

Richardson Precision West is your premier resource for on-site CNC water jet ball screw repair services. We repair Flow and OMAX ball screws at your facility to minimize total downtime – no need to ship out your ball screws or wait weeks for a new part!

We provide cost-effective field service repair of worn, loose and noisy CNC ball screw assemblies. We service CNC motion systems including ball screws, way guides and end-bearings for water jets, as well as lasers, punch-presses, brakes/shears (back gauges) and CNC milling centers.

Richardson Precision West understands down time and cost savings. That’s why so many customers choose us for their water jet ball screw maintenance and accuracy restoration needs. Our budget-friendly rates won’t break the bank to restore cut accuracy.

We pride ourselves on responsiveness – whether you are experiencing minor cut issues, or are in need of an emergency repair because your machine is down – give us a call. Our response time is second to none!

Water jet ball screws need regular service that goes beyond manufacturer preventive maintenance.

Most CNC metal-working machines tend to loosen up with age and production hours. It is very common to see water jets with only 4,000 to 6,000 hours on them showing “hole out-of-round” problems. This is not a machinery quality problem; it is usually caused a ball screw assembly worn from abrasive cutting effluents (like sand if you have a damaged or missing cover) or moisture that is compromising the integrity of the motion system.

Unless you want to pay for expensive replacement parts (most customers don’t!), regular lubrication isn’t enough. A clean, flush and inspection every 2-3 years (more often if you run 2+ shifts), will keep your ball screw motion system in peak performance. We’ll clean the motion system and inspect the ball screw for wear issues- helping you to avoid unexpected down time and extending the life of your ball screw.

On-site water jet ball screw repair services ensure the least downtime and the least lost production.

Even with travel expenses, our prices are lower than most CNC ball screw repair service depots. And, we’re an affordable alternative to OEM replacement! See our Cost Examples page for a sample comparison and contact us for a custom service quote.

Ball screw repair

doesn’t have to cost a fortune!

Contact us to learn how we can get you back to cutting quality parts

at a fraction of the cost of replacing or rebuilding your ball screw.

(And YES, we warranty our work!)